Table of Contents

ToggleWhen it comes to construction projects, one of the most critical elements is the integration of mechanical, electrical, and plumbing systems – often referred to as MEP systems.

Building MEP Drawings for contractors are essential tools that ensure all these systems work efficiently and safely within the structure of a building. These drawings offer a visual representation of how the mechanical, electrical, and plumbing systems should be designed and installed.

In this blog, we’ll break down what MEP drawings are for contractors, why they’re so important, and how contractors can leverage them to streamline the construction process.

What Are MEP Drawings?

Building MEP drawings for contractors are detailed blueprints that show the design and installation of mechanical, electrical, and plumbing systems in a building. These drawings are created by MEP engineers and are used by contractors to plan, install, and maintain these systems efficiently.

These drawings cover several essential aspects, including:

- Mechanical Systems: This refers to the heating, ventilation, and air conditioning (HVAC) systems, including ductwork, air handling units, and exhaust systems.

- Electrical Systems: This covers the wiring, electrical panels, outlets, lighting, and power supply lines throughout the building.

- Plumbing Systems: This includes water supply lines, drainage systems, and piping for gas and other utilities.

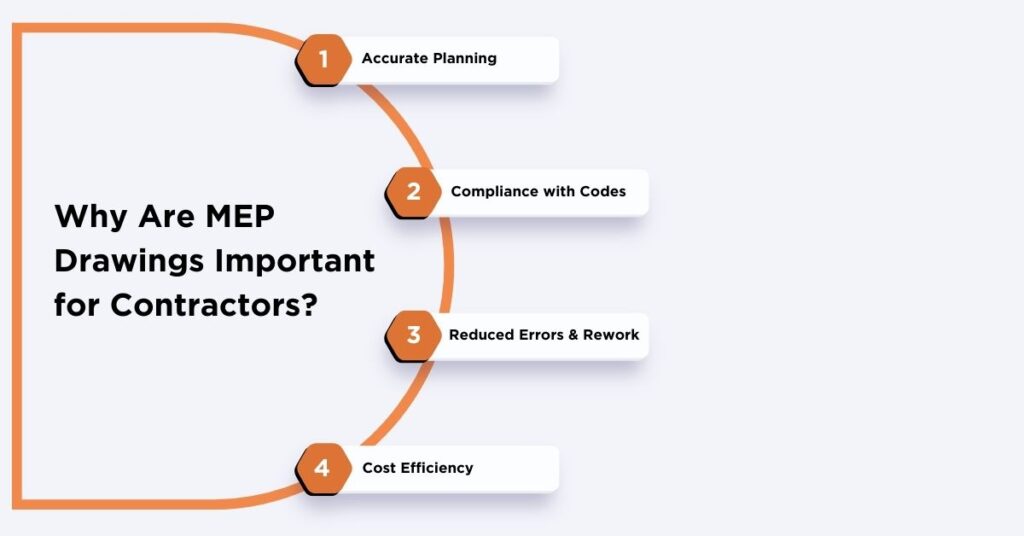

Why Are MEP Drawings Important for Contractors?

For contractors, building MEP drawings is more than just technical documents – they are the roadmap to success on the job Site. Here’s why these drawings are so important:

1. Accurate Planning

MEP drawings provide a clear visual representation of all systems, which helps contractors plan the installation and avoid potential conflicts with other building systems.

2. Compliance with Codes

Every construction project must meet local building codes and regulations. MEP drawings help ensure that all systems comply with these rules, reducing the risk of penalties or delays.

3. Reduced Errors and Rework

With detailed MEP drawings, contractors can visualize how each system interacts with the building’s structure. This helps in avoiding costly mistakes and rework down the line.

4. Cost Efficiency

By having a detailed blueprint of all systems, contractors can order the correct materials and equipment. This leads to better budgeting and fewer unexpected expenses during construction.

Key Elements of Building MEP Drawings

When creating building MEP drawings for contractors, certain key elements must be included to ensure the drawings are both comprehensive and easy to understand.

1. Mechanical Systems

The mechanical systems involve heating, cooling, and ventilation. Some of the critical components that should be included in MEP drawings are:

- HVAC Layout: This includes ductwork, air conditioning units, and ventilation shafts.

- Heating and Cooling Systems: Placement of boilers, chillers, and air handlers.

- Exhaust and Ventilation: Details about kitchen hoods, restroom exhausts, and air ventilation systems.

2. Electrical Systems

Electrical MEP drawings focus on the building’s power and lighting systems. Some of the most essential elements are:

- Electrical Panels and Switchgear: Placement of main electrical panels, sub-panels, and any special equipment like generators.

- Wiring and Conduits: Detailed wiring layouts that include outlets, switches, and light fixtures.

- Power Distribution: Location of power circuits, transformers, and distribution boards..

3. Plumbing Systems

Plumbing systems ensure the flow of water and waste throughout the building. Key components of plumbing MEP drawings include:

- Water Supply Lines: Location and size of pipes that supply water to different areas of the building.

- Drainage and Waste Lines: Detailed layout of drains, vents, and wastewater disposal systems.

- Gas Piping: If applicable, gas piping and connections must be clearly shown.

How Do Contractors Use MEP Drawings?

- Installation: Contractors rely on these drawings to ensure proper installation of all mechanical, electrical, and plumbing systems. The MEP drawings guide them on where to place ductwork, electrical wiring, pipes, and fixtures.

- Coordination: MEP drawings help contractors coordinate with other trades (like structural and architectural teams) to prevent clashes. For example, the placement of HVAC systems should not interfere with plumbing pipes or electrical wiring.

- Troubleshooting: If an issue arises during construction or after the building is completed, MEP drawings can be used to troubleshoot and fix problems quickly.

- Maintenance: Once construction is complete, these drawings become valuable for ongoing maintenance. Facility managers can use them to understand the layout of systems and perform repairs when necessary.

The Process of Building MEP Drawings for Contractors

Creating building MEP drawings for contractors is a collaborative process that involves several stages:

1. Initial Design Phase

During this phase, the MEP engineer works closely with architects and the client to understand the project requirements. They determine the needs for HVAC, electrical, and plumbing systems and begin to design the layout based on the available space.

2. Detailed Drawings

Once the design is finalized, the MEP engineer creates detailed drawings using software like AutoCAD, Revit, or BIM (Building Information Modeling). These drawings will include precise measurements, material specifications, and system details

3. Coordination and Conflict Resolution

In the coordination phase, the MEP team ensures that their designs do not conflict with structural elements or architectural plans. For example, HVAC ducts should not obstruct load-bearing walls or electrical systems.

4. Review and Approval

After the MEP drawings are complete, they must be reviewed and approved by the necessary stakeholders, including the client, contractor, and local authorities. This ensures everything meets building codes and regulations.

5. Final Installation

Once approved, the building MEP drawings for contractors are handed over for actual installation. Contractors use these drawings to set up the systems correctly.

The Role of Technology in Creating MEP Drawings

In the past, MEP drawings were created manually; now, with advancements in technology, contractors and engineers have access to powerful tools that produce highly detailed, accurate drawings.

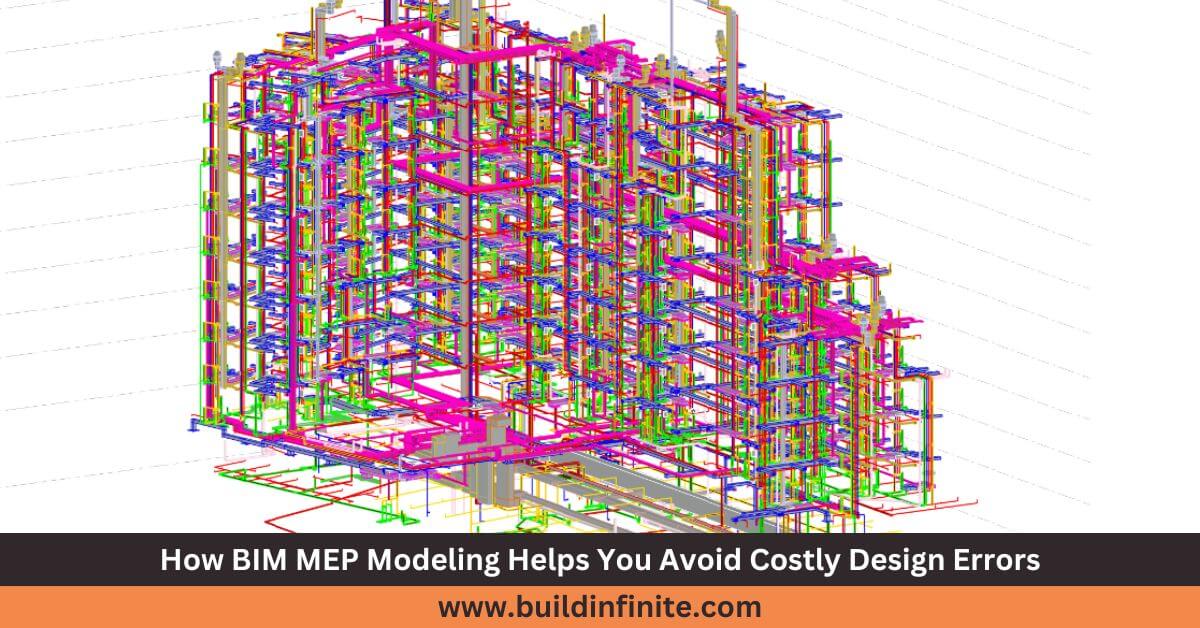

1. Building Information Modeling (BIM)

BIM has revolutionized the creation of building MEP drawings for contractors. BIM software allows engineers to create 3D models that show not just the design but also how the systems will interact in the real world. This makes it easier to spot potential issues before construction begins.

2. AutoCAD and Revit

Both AutoCAD and Revit are commonly used in MEP drawing creation. These software programs allow engineers to design and document MEP systems with high precision. They also make it easier to modify drawings and generate detailed specifications quickly.

3. AI and Automation

The integration of artificial intelligence (AI) in MEP design is also transforming the process. AI can help with:

- Automating routine tasks: AI can speed up tasks like dimensioning and routing, reducing the amount of manual work involved.

- Error detection: AI algorithms can detect clashes and design issues before they become costly problems.

- Optimizing systems: AI can help engineers create more energy-efficient and cost-effective MEP designs by simulating different configurations.

Benefits of Using Advanced Technology in MEP Drawings

- Increased Accuracy: Software like Revit and AutoCAD minimizes the risk of human error and produces highly accurate designs.

- Faster Turnaround: Digital tools allow for faster creation, modification, and approval of MEP drawings, speeding up the overall construction timeline.

- Better Collaboration: BIM and other digital tools enable better collaboration between all parties involved in the project, ensuring everyone is on the same page.

Common Challenges in Building MEP Drawings for Contractors

While building MEP drawings for contractors offers many benefits, there are also some challenges to consider:

- Clash Detection: MEP systems can often clash with other building elements, like structural beams or architectural features. It’s essential to detect these issues early to avoid delays.

- Complexity of Systems: Some buildings, especially larger ones, have complex MEP systems that are difficult to design and coordinate. Contractors need highly detailed MEP drawings to navigate these complexities.

- Changes in Design: Last-minute changes to design can create problems, especially if MEP drawings are not updated promptly. Proper communication between contractors and engineers is crucial to keep everyone on the same page.

Conclusion

Building MEP drawings for contractors is a vital part of any construction project, offering a detailed roadmap for the successful installation of mechanical, electrical, and plumbing systems. They help contractors avoid errors, save money, ensure code compliance, and streamline the installation process.

With advancements in technology like BIM and AI, creating these drawings has become faster, more accurate, and more efficient.

Contractors must understand the importance of MEP drawings and ensure they use the most advanced tools and techniques to create and implement them. By doing so, they not only improve the quality of their work but also contribute to the overall success of the building project.

Whether you’re working on a minor renovation or a significant commercial development, building MEP drawings for contractors should always be a priority.